Products

Products Description

Equipment Usage

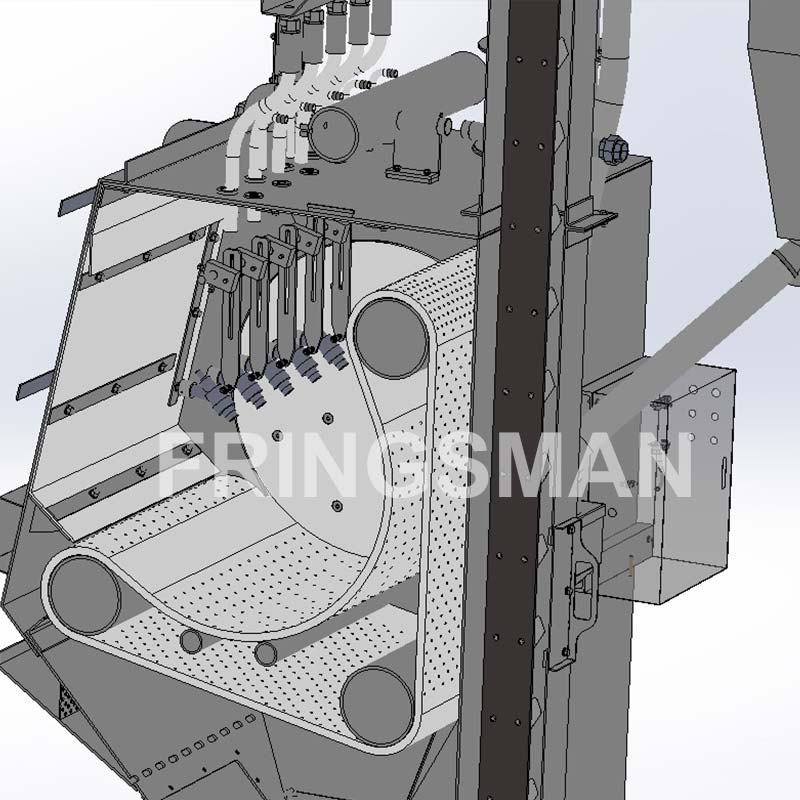

This machine is a new type of tracked automatic sandblasting machine designed specifically for cleaning small castings. The workpiece rotates on the rubber track inside the cleaning room and receives blows and friction from different directions of sand shot, causing the molding sand, oxide rust layer, and dirt on the workpiece to quickly fall off.

This sandblasting machine adopts a suction sandblasting method, which utilizes the injection effect of negative pressure generated by the high-speed flow of compressed air in the spray gun. The abrasive in the cyclone separator is sucked into the spray gun through a sand pipe, and then sprayed out at high speed with the compressed air from the nozzle to achieve sandblasting treatment on the surface of the workpiece.

The sprayed abrasive falls into the bottom of the cleaning room and is transported by a screw conveyor to the lower part of the elevator. It is lifted by the elevator to the air separator, and the qualified abrasive after separation is transported to the storage bin for recycling.

| No. | Feature | FL226 | FL2210 | |

| 1 | Max. load | 200Kg | 600Kg | |

| 2 | Max. single piece load | 10K | 30Kg | |

| 3 | Automatic shot peening system | No. of nozzles | 5sets | 6sets |

| Sand blasting quantity | 5×400Kg/h | 6×400Kg/h | ||

| Compressed air pressure | 0.6-0.75Mpa | 0.6-0.75Mpa | ||

| Compressed air consumption | 12-18m3/h | 16-20m3/min | ||

Leave us a message

Related products

Related products

- Hanger type shot blasting machine

FL5220 Hanger type shot blasting machine

Rated 0 out of 5Read more - Shot blasting machine

FLGW300 Steel pipe outer wall special shot blasting machine

Rated 0 out of 5Read more